MMX-PRESS - MEGA MIX 8 - 18 to

MEGA MIX - Size that inspires!

TROPPER produces the grinding and mixing plant MEGA-MIX in mixer sizes of from 8 t to 18 t volume. The highly stable aluminium mixer drum combined with two upright mixer screws and high performance drive ensure increased suction and blowing performance.

The new MEGA MIX Duo – Flexibility for large mixes!

With the TROPPER MEGA MIX Duo new dimensions are opened up for contractors: the light but strong aluminium mixer drum can accept a volume of from 10 t to 18 t of fodder at a maximum vehicle height of 4 m! In the MEGA MIX Duo the mixer is equipped with a revolvable partition. You can produce two different fodder mixes at the same time.

Factors for success of contractors:

Long-term MEGA MIX advantages:

Ask your advisor about the advantages of Tropper Grinding and Mixing plant:

Mr Josef Niedermayr

niedermayr@tropper.at

Mr. Johannes Tropper

hannes@tropper.at

MMX-Control Profi in Central Operator Controll Box:

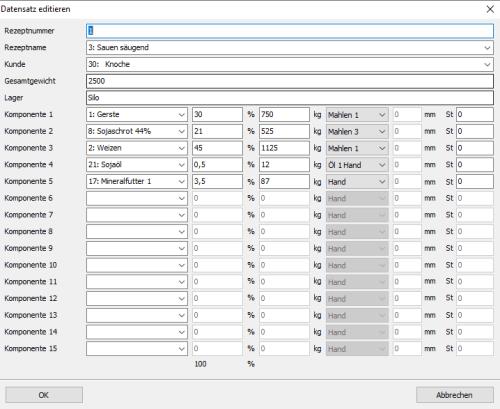

The modern new mixing system control MMX Control Profi from TROPPER, which is available in 9 languages: Backlit, bright 10 “color display (operating temperature -20 ° C to + 70 ° C) with robust keypad, equipped with numeric keypad and 16 function keys;

Software with its own SQL database for easy customer management of 10,000 customer addresses, recipe management, 15 components per recipe, printing a delivery note, batch storage, managing data on the operator panel and simple data exchange with a PC using a USB stick as well as via remote maintenance using a GSM module or conveniently from a notebook the cab.

Recipe control → printouts possible

For clear and accurate processing of recipes using a user-friendly interface.

Successful drive systems

AUXILIARY ENGINE STAGE V:

Standard is the economical powerful Scania engine with 331 kW and 450 hp installed

DIRECT DRIVE:

Tropper direct drive with elastic, compensating coupling.

Both drive options from TROPPER provide, due to the low maximum working revolutions of 1,600 rpm when sucking, for optimal performance and torque at low fuel consumption. Modification for plant oil is possible for both types!

Tropper Airblock

With the smooth running Airblock you can count on a well-protected air-end with temperature monitoring.

Optional: TROPPER AIRBLOCK DUO POWER

The MEGA suction station for even more suction performance at low revs. Save fuel and spare the direct drive due to lower rpm despite higher performance.

Hammer mill HM 660

The mill is standard equipped with 160 hardened metal hammers (with 1,1 m² filter surface) and therefore also well suited for special purposes such as grinding moist grain. (Grinds up to 35 t/h).

Filter exchange is easy to carry out.

Grain crusher QR 600

In the case of the massive, hydraulically adjustable crusher the crushing performance and the crush quality are always the main priorities. The large 600 mm long crushing rollers with a diameter of 400 mm and the proven belt drive enable top throughput with all fodder ingredients. Simple crushing gap adjustment while running is a specialty of the TROPPER crusher.

Magnetic separator

Despite the strong magnetic force the magnetic separator can easily be taken out and wiped clean. Order number: ID 02499.

Complete draining since 1992

As an operator of mixing plants, you set great store by a quick and clean change of products. Hereby, you can rely on our long-time experience with pneumatic discharge. TROPPER MMX-Press have been drained, according to a simple and efficient system, since 1992 for a simple and effective system: Due to maintenance-free outlet plates, the best possible draining can be achieved without any complex mechanics at the bottom of the mixer drain! In combination with the standard hopper knocker (cleans the mixer wall) and the draining stop, you can achieve impressively clean results. You as customer supply high-quality compound - hence: mix quality - avoid loss!

Additional material hopper in stainless steel

With suction, elastic and mounted very low (optimal height for adding ingredients) with a table and a bag opener for small bags as well as a shaker for emptying the bags fully.

Blower arm with double joint NW 100

optional NW125

The special hydraulic full stream technology enables dust-reduced discharge of large amounts of material due to the 2 joints.

Optional discharge screw instead of blower arm

For complete discharge of the mixer contents and for continual throughput crushing (e.g. for biogas plants). When carrying out continual throughput crushing the crushed grain is guided through a rotary feeder.

Fluid addition for oils

Suction system with tubes, regulator and intake lance as well as oil tank (300 l to ca. 2,000 l) with counter (select amount). Figures are displayed on the weighing computer (MMX Control).

Hot galvanized frame components

TROPPER sets high quality standards and has its processed frame components hot galvanized after they have been bevelled!

Sound insulation hood in attractive design

The complete internal coating of the aluminium hood with high quality sound insulation material enables on the one hand effective reduction of the operational noise and on the other hand easy access to the units due to the large cover.

Comprehensive standard accessories

It is a matter of course that all necessary parts such as hoses, suction tube, exchangeable filters etc. are included at the time of delivery so that as soon as you accept the vehicle you can start working with it. TÜV inspection in our works is obligatory for DE and AT.

Your special standard equipment:

- Camera set for reversing

- Storage box for hose etc.

Improve safety thanks to the practical camera set with digital display on the monitor in the cab.

Made of aluminium, at a low height with trays for suction lances and coupling pieces, weather protection roof over the additional material hopper, tools in a toolbox as well as a fire extinguisher which are naturally all included!

|

|

||

|

|

Language

Language Deutsch

Deutsch Français

Français Español

Español русский

русский